Microcontrollers at 3°C

Networking on multiple levels

Ever spent a week at 3°C with microcontrollers and sensors? We have. We are Corinna Aufderheide and Anne Mayer and in this blog post we would like to tell you about our experiences in the lecture "Industrial Production and Industry 4.0" and give you some insights into our last semester.

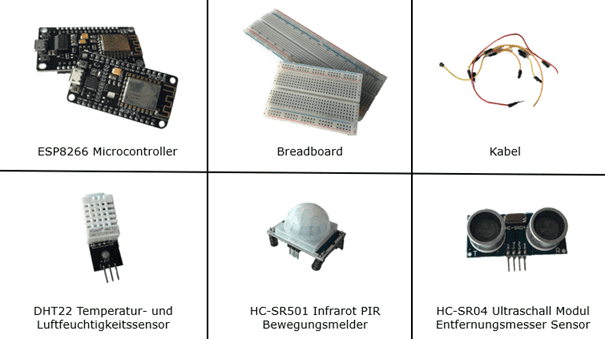

"Industrial Production and Industry 4.0" is a lecture in the second semester of the 4-semester master's program Industrial Engineering. Beforehand, we were given the task to order some hardware components like a ESP8266 Microcontroller, breadboards and a sensorkit with seemingly endless possibilities. Due to the lack of prior experience with microcontroller and sensor, we were overwhelmed by the variety of the sensors to choose from. During an introductory session Prof. Drumm and Prof. Meinecke gave us various examples of what can be done with the sensors. For example, we learned how to trigger an LED when pressing a button or how to measure temperature and humidity in a room.

The following image shows a few of the components we used in our project.

At this point We were very glad that we took the Python introductory lecture in the previous semester. This enabled us to quickly program the microcontroller using PyCharm and to analyse data using Jupyter Notebooks. In addition, we were also introduced to the AWS IoT Services. These are cloud services provided by Amazon to collect and process large amounts of data.

Industry 4.0

But the question that interested everyone in the course: What do I do with all this in real life?

Industry 4.0 - as the fourth industrial revolution is known - has become an integral part of the industrial context. It is about digitalization and the intelligent networking of machines and processes using internet technologies. The possibilities and potentials that Industry 4.0 holds for industrial production were the central topic of the lecture taught by Prof. Drumm, Prof. Meinecke and Prof. Luft. In addition to the introductory session, we were provided with 12 learning videos on different topics in the context of Industry 4.0. The topics included cyber-physical systems, cloud computing, Big Data, business analytics and the autonomization of production. The underlying question always was: How can industrial production be supported and improved using those technologies?

A real-world use case

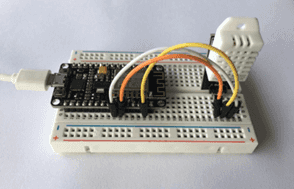

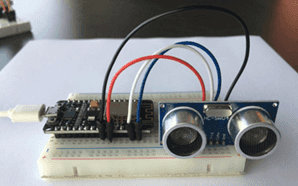

Building on this question, we were asked to find a use case for an IoT project. The goal was to investigate a real-world problem by recording data using sensors and microcontrollers, storing the data using AWS IoT service, and then analyzing the data to generate some insights. If possible, the use case should be in an industrial context. This was a big challenge for most of the students due to the pandemic situation. We were lucky and were able to conduct our project together with a company. Through research and several discussions, we came into contact with a logistics service provider that specializes in the storage and transport of frozen goods. For this company we implemented a project in which we examined temperature changes in a cold storage hall for fresh products. For the project microcontrollers were attached to all doors of the cold storage hall as well as to the ceiling. The microcontrollers were connected to 5 motion sensors at the gates and 9 temperature sensors distributed throughout the storage hall at heights of 2 and 8 meters. The images below show the prototypical setup with a temperature sensor and a motion sensor respectively.

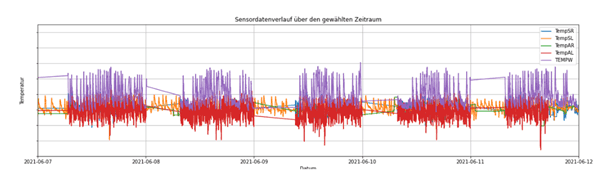

Within a week, 2.5 million data points were collected using those 14 microcontrollers and sensors. All this data had to be analysed afterwards.

Some difficult problems

We worked several hours per week on the project, and it was a strain on our nerves. In contrast to the "laboratory conditions" at home, WLAN interruptions, daily resets and inexplicable phenomena in the industrial context were more difficult to analyse and solve on site. But we also learned first-hand what to look out for when carrying out a project in an industrial setting. For example, we learned a lot about data protection, the right choice of sensors and that working in a cold storage hall at 3 °C can be really tough.

We also had to deal with the problems that arose from the people working in the storage hall. For example, we discovered that an infrared sensor also reacted to the body temperatures of the employees behind the gates and provided unusable data for the project. We therefore decided to use ultrasonic sensors instead.

We also had to deal with WLAN dropouts at night. These can be seen in the image below. For some unexplained reason WLAN connection of the microcontroller stopped every night. A software solution was not successful here and the application of a hardware reset was not feasible in the short project phase. Therefore, the only option for us was a manual reset every microcontroller every morning with the help of an employee of the logistics company in order to record suitable data.

During programming and analysis, further problems arose due to the high number of data. All the data stored in AWS had to be cleaned and changed to the same format. This resulted in high run times for the data analysis program. As a result we had to learn about parallel processing in Python on our own to be able to present a descriptive and fast solution.

Our results

After the analysis, we presented our results to the logistics company and made the analysis tool available to them. Based on our analysis the logistics company will start to work on the detected problems and thereby improve the cold chain for fresh products.

Some thoughts on the lecture

The project was a real challenge through which we were able to learn what it means to carry out a project in practice. Through our perseverance, we were ultimately able to create value for our project partner. In summary the lecture gave us the opportunity to gain valuable experience in practice and to experience for ourselves how Industry 4.0 technologies can be used and what their potential is. With the expansion of our network, knowledge and experience, the high effort of the module was definitely worth it.